If your design calls for a hollowed-out body a high-speed rotary multi-tool works nicely. Well cover this in a bit.

Co2 Dragster Dynamics Howstuffworks

I first laser printed my design on the wood then I used a saw to cut it out.

. Review Tips- Physics Avoid unnecessary extensions and ornaments that add weight to your car. CO2 drag cars are far more similar in design and principle to jet-powered land speed racers than they are a fuel car. Generate Ideas Round front Pointed front Balanced front and back weight Front and back are even Narrow Curves Tails to keep airflow attached Steep front Constraints Criteria Amount of drag Number of vacuums.

Do you want to focus on the cars performance or appearance. Gravity - force acting on a car trying to hold it down to the earth. Below are some highlights.

How Do You Make A Co2 Car Step By Step. Speed at any price show-stopping good looks or some combination of the two. How fast is a 1000 hp car.

A variety of milling and sanding bits are helpful for making cavities in the. The second step is to print your design and cut it. Screw eyes are optional but can be used to run a string or wire through them to make sure the car goes in a straight path on a CO2 car track.

Allow for the weight of paint coats too. Take your car home and apply spray paint andor decals optional. The car should roll freely and the wheels should spin without restriction.

As a CO2 car is essentially a jet-powered vehicle it requires no power. In this equation the weight of the vehicles front and rear is taken. Reduce the drag and lift rate.

I do not know exact measurements for materi. You will get the best results if you combine basic shapes. It is possible to reduce the aerodynamic drag of CO2 cars by shaping the rear section in a boat-tail form.

Insert axles through the straws. In 2007 the United States Environmental Protection Agency EPA and. CO2 Dragster Design and Construction Tips Designing a CO 2 Racer Before putting pencil to paper consider these important points.

The basic shape of the dragster has a thin rail connecting the front. The fifth step is to use washers. Follow the specifications given to you for the car.

I used CorelDraw x3. These cars can be dangerous. The PRO Driller for drilling perfectly straight axle and eyelet holes.

On 29 March 1927 Henry Segrave drove the car to a new land speed record of 20379 miles per hour 32797 kmh the first car to reach a speed over 200 mph 320 kmh. Obviously this is how large and heavy the car is. Due to its symmetrical shape the sphere is an aerodynamically good shape.

The first in a three part series Dan and Ray explain the what when it comes to the basics of CO2 racing. Forces That act upon a Co2 cars Lift - an upward force resulting from air being forced underneath a car. The third step is to drill holes.

Simply put the less weight your dragster has the faster it will go. However we used some aspects of shell and show cars to make the design more aerodynamic and aesthetically pleasing. This is the most important factor that will figure into your design.

This project is simple takes about 3-4 hours and only costs around 10-20. The gas escaping from the CO2 cartridge in the car. In a rail design the wheel and other parts of the dragster are exposed which naturally increases the drag.

The Sunbeam 1000 HP was the first non-American car to run on Daytona Beach for a land speed record attempt. Make sure that your drill holes are straight and accurate to reduce extra forces acting on your car. Top Fuel dragsters look the way they do because their primary design criteria is to channel more than 8000 horsepower through a little bit of rubber.

Review Tips- Painting your car will reduce aerodynamic friction. I did this project in class and it was a lot of fun. Cut two pieces of soda straw 1-58 long for bearings.

CO 2 dragsters are cars used by miniature racing cars which are propelled by a carbon dioxide cartridge pierced to start the release of the gas and which race on a 20 metre track. The fourth step is to add Axels. 57 Flow simulation of Co2 car design Fig.

The axles fitted into dragster cars need to be as short as possible. They are frequently used to demonstrate mechanical principles such as mass force acceleration or aerodynamicsTwo hooks eyelets or screw eyes linked. STEM Learning Activity CO2 Dragsters.

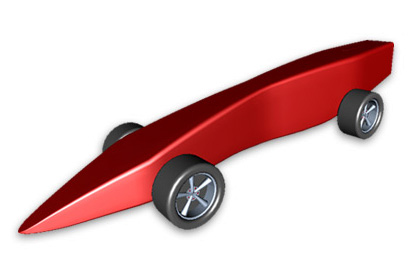

What is most important to you. Speed clean your house in four easy steps by. Our CO2 car best conforms to the rail car design most typical of student-made dragsters.

Drag - air resistance that pushes against a vehicle. CO2 cartridges can explodeMaterials. Building your Dragster or Blastcar.

See more ideas about co2 cars co2 dragsters. How To Design The Best Co2 Car. If you want to build the quickest and most aerodynamic CO2 dragster possible than you need to figure out the best shape and design.

When weighing your car put the wheels axles washers screw eyes and any other necessary hardware on the scale along with the body. Finish smoothing the car using finer and finer grit sandpaper. This allows air to flow over the surface of the structure without causing any disruption to the air flow.

Design Go Speed Racer Co2 Car Project Dragster 2 0 Co2 Car Stem Software Application Whitebox Learning 14 Co2 Cars Ideas Co2 Cars Co2 Dragsters. Sep 12 2017 - Explore madi popas board CO2 Cars on Pinterest. Here are some of the principal forces involved.

Roll test the car on a smooth horizontal surface. The lighter you design your car the more power will be used out of your CO2 cartridge. Designing your car - CO2 Car Design Styles.

And Dynamic Radar Cruise. Improvement of driving characteristics. Insert the CO2 cartridge into the hole in the back of car.

Thrust - a forward force produced by an engine or turbine. The first step is to create a design. 71 Flow simulation of Co2 car design Fig.

Insert one straw through the front axle hole and the other through the rear axle hole. Winning Blastcar Secrets covers everything from how to build a Blastcar track to designing and building a winning CO 2 Blastcar. 72 Flow simulation of Co2 car design Reduce the fuel consumption.

Learn what works and what doesnt work.

Unit 4 Grade 09 Exploring Technologies Project Research Design And Build

Dragster 2 0 Co2 Car Stem Software Application Whitebox Learning

How To Make A Co2 Car Text Images Music Video Glogster Edu Interactive Multimedia Posters

Co2 Dragster By Reddinosaur Lumberjocks Com Woodworking Community

Building A Co2 Race Car 6 Steps Instructables

Co2 Dragster Derby Engineering Design Technology

Crazy Fast Ghs Co2 Powered Dragster S Design S And Races Youtube

Unit 4 Grade 09 Exploring Technologies Project Research Design And Build

0 comments

Post a Comment